How to keep silage effluent off clean areas?

A sleeping policeman or a channel across the front of the silage clamp? Which should you choose, and is there another option to consider? Before I can really give my view on these questions, we really ought to explore what you should be trying to achieve here and what problem we are trying to solve.

Why does a silage clamp need a sleeping policemen?

Well it’s got nothing to do with speed humps has it - or actually has it? Reducing speed might be useful in some situations but we will come on to that. The main purpose of a sleeping policeman or a channel is two fold; firstly to keep runoff separate between two yard areas and secondly to ensure the run off goes where you intend it to go - usually to a drain or gully connected to the silage effluent tank.

A clear channel is important to control effluent

The number one enemy when designing a silage clamp is the effluent. That stinking forage juice that ruins your clothes, gets under your fingernails and up the noses of your non farming friends and relatives is everyone’s enemy number one. Silage effluent IS the pollution risk and it is therefore, the focus of most of the rules and regulations that surround the storage of silage. Keeping this effluent contained is critically important and a sleeping policeman or channel can help make sure it ends up where it should - in the effluent tank - and not where it shouldn’t - in a water course.

High dry matter silage doesn’t produce effluent so do you still need effluent channels and tanks?

Yes you do - because the rules in the UK say you do. Effluent is sooooo pollutive that the SSAFO regulations do not allow for any interpretation or variation. A compliant clamp must provide effluent containment that ensures any run-off drains to the effluent tank. And even if you don’t anticipate producing silage effluent because you are (and should) be making higher dry matter silage that doesn’t produce any significant effluent, there are still good reasons to carefully plan this containment and separation of floor areas.

This is because any rainfall run off from a floor slab that stores silage is considered “dirty” where as yard areas that are just exposed to farm traffic can be considered as “clean”. This means you must contain the run off from the “dirty” areas and all this water needs to be disposed of via the farm waste management system. Run off from “clean” areas doesn’t need to go into this system so maximising “clean” areas and minimising “dirty” areas can massively reduce the costs and the headache.

Joints either side of the channel are difficult to seal

Can floor falls keep my silage effluent safe?

In a perfect world you might be able to achieve the containment of effluent with different floor levels and falls. However I never visited the perfect world and back in normal world there is enough muck and bullets to scupper this plan. The biggest issue is trying to minimise just how much rainfall gets into the effluent system from the “clean” concrete areas. In reality you need to minimise what you collect and ensure that the effluent doesn’t escape, so a channel or hump is a safe way of ensuing you don’t pollute by accident - but which is best?

Both have their disadvantages but in summary - channels are expensive and block up, whilst humps are a pain to drive over and can cause a lake. And as neither of these sound very attractive, what other options are there?

The easiest one of these to answer is the last one - because no there isn’t really any sort of alternative, there are just variations on the first two!

What is the best sort of silage effluent channel?

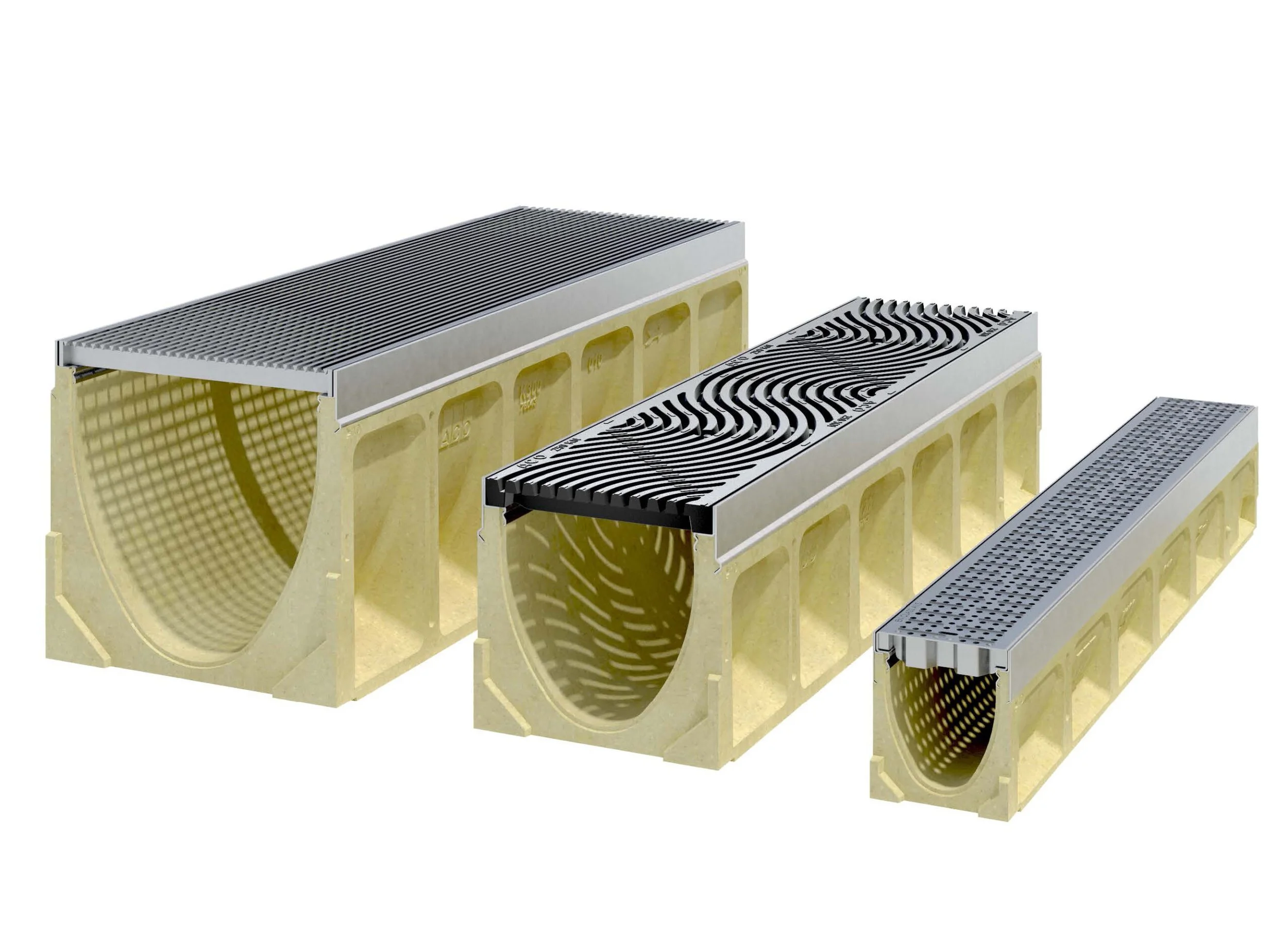

There are lots off different ways to form an effluent channel across the front of a silage clamp. The most comprehensive (and expensive) is a preformed channel such as an ACO Drain, just like you see at the fuel station forecourt. These are usually formed in polymer concrete, plastic or resin that’s resistant to silage effluent and they come in a range of depths and widths to suit the clamp width. The removable grates are suitable to HGV traffic too so what is not to like!

Polymer channels such as ACO are available in many sizes

Well the cost for a start but if you can get over that they do offer a very nice solution. The other significant down side is the fact that the channel gets blocked up with fine forage so they need to be checked and cleaned out as required. As an alternative you can buy preformed dish channel units made in pressed concrete - a bit like road kerbs. These are much easier to clean out when they get blocked with fine chopped forage, as are site formed “T” channels capped with timber sleepers. But the main issue you can’t get away from with any of these options, is the joint between the channel and the floor slab.

Precast concrete effluent channel by Craven Concrete

If you are forming any sort of low level channel, it’s usually constructed first and then the floor and/or apron slabs are laid up to the channel. This creates joints that need to be sealed. Joints that are situated in really high traffic areas, and joints that are really, really hard to keep sealed. And joints that often result in the channels “sinking” or settling over time.

Why a policeman might be your friend.

The main advantage of a hump or sleeping policeman is that it can be formed within, or on top of, the floor slab so it eliminates the joint issues of channels. In my opinion this is a massive advantage, but many operators detest the rough ride as you drive in and out of the clamp. This uneven surface is also something that needs to be considered if trailers are going to be tipping in this area. Axels approaching the hump at an angle can seriously upset the balance of a tipped trailer body - so the hump needs to be carefully positioned.

The sleeping policemen position is as important as its height - but how high should it be? Well sleeping policemen came in as many different sizes as wide awake ones. What’s important is that the effluent will run off to the drain before it comes over the top of the hump. This is site specific and needs to be calculated by someone who knows how - but the answer is usually between 75mm and 150mm high (3”-6”).

What is the best shape for a sleeping policemen in a silage clamp?

I usually try to design a tapered hump profile that has a shallow rise as you approach the clamp and a steep drop on the other side. This makes for a better drainage profile as the flow rate is higher on the steep side making it better at “self cleaning” and it also has some beneficial traffic calming effects. If you are driving into the clamp the hump is not too aggressive, but when driving out its a bit more severe. This can be helpful on a busy site because your sight lines are poor driving out of there clamp as the walls obscure much of your view. The vehicle is also going into a busier area where pedestrians and other traffic is more likely. So if you’re going to have to slow down for the hump it’s no bad thing.

Sleeping Policeman is easy to construct in asphalt

The final benefit of a hump over a channel is when it comes to maintenance in the future. Its much easier to overlap a floor slab with 40mm of asphalt when there is a hump at the front rather than a channel.

If you want to discuss the best way to contain the effluent within your silage clamp or would like to discuss any other aspects covered in this series, contact me at jeremy@silageconsultant.co.uk