Steering silage trailers into the future

Agricultural kit keeps getting bigger, and much much more expensive! Mowers, rakes and harvesters all keep getting bigger and more powerful with ever higher outputs to justify their ever climbing price tags. And the trailers that run along side all this kit are not forgotten either. Back in the day a 10T silage trailer was a big beast, today 18T & 20T trailers are not uncommon. This all came into sharp focus when a contractor, who had unintentionally removed a gate post, politely asked if its replacement was going to be in the same location? On hearing the news that the gateway was going to remain at 12’ wide he expressed some considerable disappointment - I’m sure you get the picture without the colourful language.

Maize silage in a Broughan trailer

Getting big silage trailers through little gateways

So just how can you get a quart into a pint pot - or more accurately an 18t tri-axle in through that 12’ gateway? It’s a problem that the worlds best engineers have not ducked and the answer seems to be to steer the trailer from both ends. Steering axles on large capacity silage trailers is not entirely new, but it is the focus of a lot of recent engineering development in an effort to safely, efficiently and quickly move forage away from the harvester and back to the clamp. Bigger capacity trailers can make harvest more efficient and compactor trailers can have a role to play, but there is no substitute for increased manoeuvrability .

Steering axles to reduce costs

Steering the axles of a silage trailer can make the whole rig much more nimble and manoeuvrable in a tight spot. If you’re not convinced, just watch a 40” combine header exit a field and join the road on the back of a four wheel steer header trailer; what seemed impossible almost looks like child's play. But manoeuvrability is only part of the story. Steering trailer axles can also drastically reduce tyre wear - by up to 60% - and reduce damage to grass sward in the field too. The costs of replacement tyres is no longer insignificant so if a steering axle can double or triple the tyre life then can it pay for itself over the life of the trailer? Possibly but this depends on what sort of use the trailer gets. A trailer that’s doing lots of shunts in tight yards hauling grass silage from small forage paddocks can suffer significant torsional stress on the chassis, massive tyre wear and cause lots of damage to the sward. The same trailer doing long draws to a huge AD facility is a completely different economic proposition.

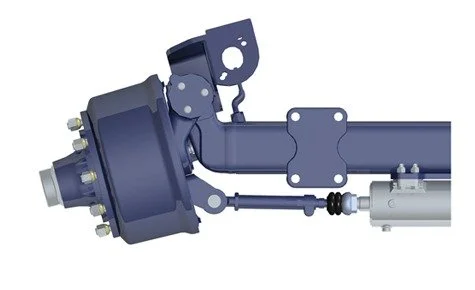

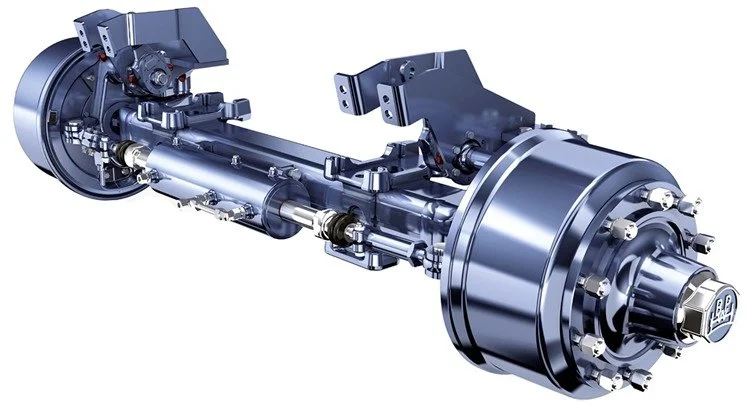

Steering trigger-axle by Smyth Trailers

Are trailers with steering axles safer?

There are mixed views when it comes to safety with steering axle. Passive (self steer) axles can feel like an accident waiting to happen if the axles are un-locked at high speed on the road. However active steering axles are promoted as having improved road safety, so what’s going on here? Well its horses for courses and a large trailer with an active or forced steering axle is much more stable under braking and cornering than one with a rigid axle. This might be something that becomes compulsory over time but the increased stability is definitely something that’s noticeable from the tractor seat.

Silage trailer steering axle options.

So clearly a steering axle is only really a benefit for trailers with two or more axles. Trailers with more than three axles are not popular in the UK because they can’t carry any increased payload over a tri-axle so there is very little benefit in running more than three axles. For two and three axle trailers that are steerable, at least one axle is going to be fixed or rigid. This then begs the question of which axle(s) do you want to steer? In most cases the rear most axle is the steered axle. This effectively reduced the wheelbase of the trailer as it turns but increases the tail swing. On three axle trailers it’s usual to fix the middle axle and steer the axles either side around the middle but that’s not always the case. By fixing the front axle the wheel base is further reduced making it even more manoeuvrable, but the greater tail swing may then become a problem.

What types of trailer steering axle is best?

So once you have chosen which axle to steer, you then need to decide how to steer it - either passively or actively. Passive is cheaper, simpler and does what it says. Passive steering basically uses axle location geometry to generate forces on the axle when turning to push the wheels into a steering angle against a spring or cam pressure. In practice this usually has a hydraulic connection to the tractor; with the spool valve set in “float” to let the axle steer and with the spool closed to lock the axle up.

Self steering axle by BPW

Casters allows wheels to steer like a supermarket trolly but must be locked at speed and when reversing.

There is little to go wrong and the system is more “affordable” but it is not quite as good at eliminating scrubbing and tyre wear as an active system and needs the driver to lock and un-lock the axle to keep the trailer safe - particularly at speed and when reversing.

Steering axle option on a Richard Western silage trailer

Active (or forced) steering requires some hydraulic (or gas) pressure to steer the wheels where they should be going. A closed pressured system can do this automatically but to work out how much to turn the wheels, the angle between the tractor and the trailer needs to be measured. This is done by fitting an additional bar alongside the drawbar, that acts on a set of levers connected to a hydraulic cylinder. The oil displaced as the piston in the cylinder moves transfers into a slave cylinder on the axle and steers the wheels, whilst an accumulator maintains a constant pressure in the system. All this works automatically with no input from the driver.

With an electronic system a linkage simply measures the angles with an electrical position sensor and the “brain” then decides how much oil to send to the steering ram. The programme usually reduces steering angles at higher speeds to make the trailer less twitchy whilst giving the full benefits at low speed. Some electronic systems also enables the driver to “over ride” the system and add steering when needed, perhaps on a slippery slope . Whichever active system, it usually allows the trailer to steer predictably in reverse and that can be a big benefit in a tight corner. All the systems have many benefits but can also be lethal in the wrong hands so an “operator” rather than a “driver” is needed to be used safely. The hitch also needs to be considered too because a simple ring and hook probably has too much slack to allow an active steering system to work properly; a ball and spoon is the usual solution. There are also ball and spoon hitches that measure the trailer angle without any additional linkage - very neat.

Counting the costs

Adding a passive steer axle to a new trailer will cost around £4000 whilst an electronic active system might almost double that. With replacement tyres costing at least £1500 per axle you can see how this option might possibly add up but this is only half the story. The real benefit of steering axles might just the the fact that you can use one less trailer in the fleet. By increasing the capacity of the trailer whilst maintaining the manoeuvrability you might be able to either drop a trailer and tractor, or increase the chopping capacity without adding another tractor and trailer. According to the NAAC this is currently worth around £65-£75 per hour, or maybe £3,500-£5,500 per week. All of a sudden those axles look a whole lot better prospect! Now admittedly you might need more than one bigger trailer to realise these savings but it’s certainly worth considering. You might also want to build in a higher resale value for the trailers at the end of the day but I suspect this might be offset by some additional maintenance costs while you were running the trailers.

Large capacity K Two tri-axle trailer

So if you’re looking at saving costs during the harvest operation, then maybe you have to consider spending some more hard earned. Although they are not quite as sexy as a 1000hp chopper or a 20t loading shovel, the trailers you are running are every bit as important as the rest of the silage fleet. Steering axles might just make it possible to step into the future through the gateways of the past.

If you want to discuss how to evaluate the your silage fleet or to discuss any other topics covered in this series, then please contact me at jeremy@silageconsultant.co.uk